Slot Milling Depth Of Cut

Cutting a.020' wide slot to the length and depth you want would be murder with an end mill. A slitting saw is what you need. Of coarse, a slitting saw will not give you a nice square end and that is what you need, you may have to finish with an end mill. Key slot milling – roughing of full slot Side milling – finishing all around the slot, using up-milling to create true square corners The radial depth of cut should be kept low in finishing operations to avoid deflection of the cutter, which is a major cause of bad surface finish and/or deviation from a true 90° shoulder.

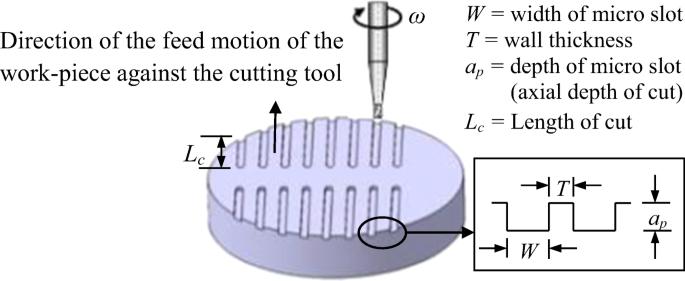

The workpiece is fixed firmly on a milling machine and fixing the end milling cutter on an arbor, by adjusting the depth of cut, the work is fed against the cutter to cut the groove on the work surface. Gang milling Operation. The tool will use climb milling while machining the pocket, which offers better cut conditions on rigid CNC machines. 4 – Slot Milling. Slots can be machined with a variety of methods including contouring, pocketing, or specialized slot milling operations.

I am having so much fun building the simple (now that I have extracted the dimensions from the v-block body!) V-block clamp straps out of 1018 (pretty

much the first time I've cut steel with my mill) that I would like to try to cut clamp straps for the second side of the dual sided McCue V-block out of 4140/12L14.

much the first time I've cut steel with my mill) that I would like to try to cut clamp straps for the second side of the dual sided McCue V-block out of 4140/12L14.Naturally, I have questions.

1) Is the 12L14 alloy of 4140 a good choice for this application?

Slot Milling Depth Of Cut Tool

2) What should I cut it with as far as end mills and drill bits are concerned? I used Putnam HSS end mills for slotting the 1018 straps and Chicom TiN coated HSS (I guess it was HSS; it worked, anyway) to make the major cuts in the 1018. Should I switch to something else for the 4140/12L14? (It is more important to me to use the right stuff to learn than to actually produce the part.)

3) McMaster-Carr wants $52.45 for a 2'x2'x12' piece of 4140/12L14. Is this about right or should I look somewhere else? If so, suggestions?

Slot Milling Depth Of Cut Files

4) McMaster-Carr 'quarantees' a tolerance (both width and thickness of -0.004'. I really do not know what 'thickness' or 'width' tolerance may be other than that is maxium amount the square bar will deviate from straight over some given length? ANYWAY, my workpiece must wind up 2.00' square. Should I get wider and thicker raw stock from McMaster-Carr and machine down to what I want? (I

think the answer is pretty much 'yes.')

think the answer is pretty much 'yes.')5) I have never been able to calculate speeds and feeds. However, I was very successful with the 1018 by turning the spindle at 540 RPM and experimenting with feeds at 0.050' DOC until the chips turned tan. (Actually, most of them were only half tan. It is my GUESS that before the whole length of the chips could heat up to turn color, they cooled sufficiently to stay bright.) I never took more than 0.050' at a time. This did not work the mill very much, but I could certainly tell the difference between 0.050' DOC in 1018 and the same in aluminum.

6) If I do my part (rather doubtful), will 4140/12L14 provide a good finish?

Thanks for any information and guidance you may provide!

--Bill